TS2000-IFE Series – MPI Most Versatile 200 mm Platform

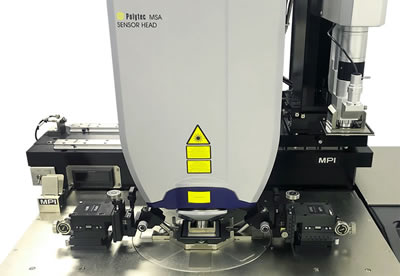

The MPI TS2000-IFE is automated platform which can be converted since the beginning or at any time later in the field to a fully-automatic probe station.

It incorporates MPI advanced technologies, such as PHC™ as a standard feature and mDrive™ or VCE™ optional or as an upgrade.

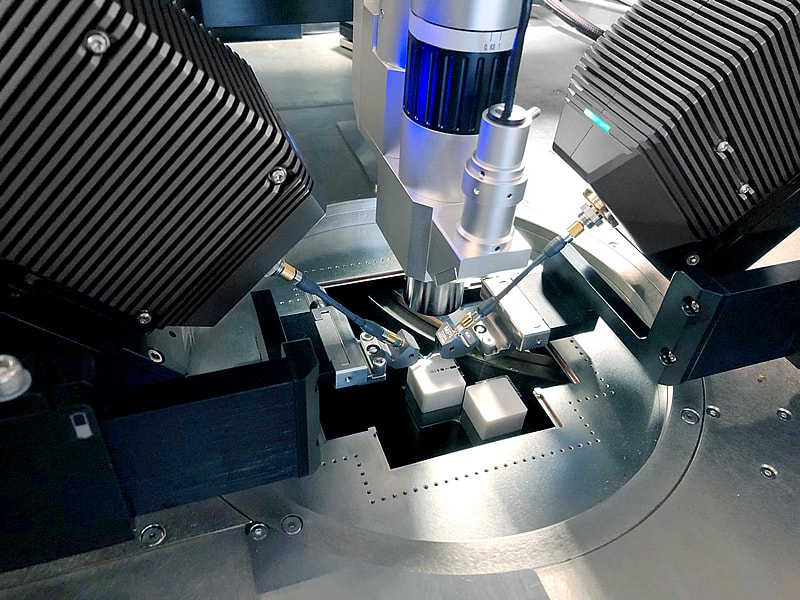

The main applications are load-pull, RF, mmW, Silicon Photonics, Design Validation (Product Engineering) or testing of MEMS and other sensors under defined test environment. In combination with WaferWallet®MAX MPI is addressing the transition from Lab to Fab for these specific applications.

Features & Benefits

WaferWallet®MAX – 10x Higher Productivity

MPI’s WaferWallet®MAX is field upgradable and addresses the demand for faster time to market, collecting data from multiple 100 or 150 or 200 mm wafers, and ramping-up tests into a pre-production environment.

With the fastest thermal transition time, reduced soaking time, advanced alignment technologies, cassette or wafer hot-/cold swapping WaferWallet®MAX is increasing system productivity and test cell efficiency up to 10x times.

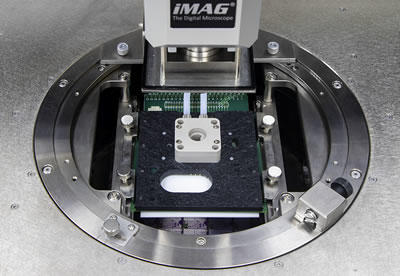

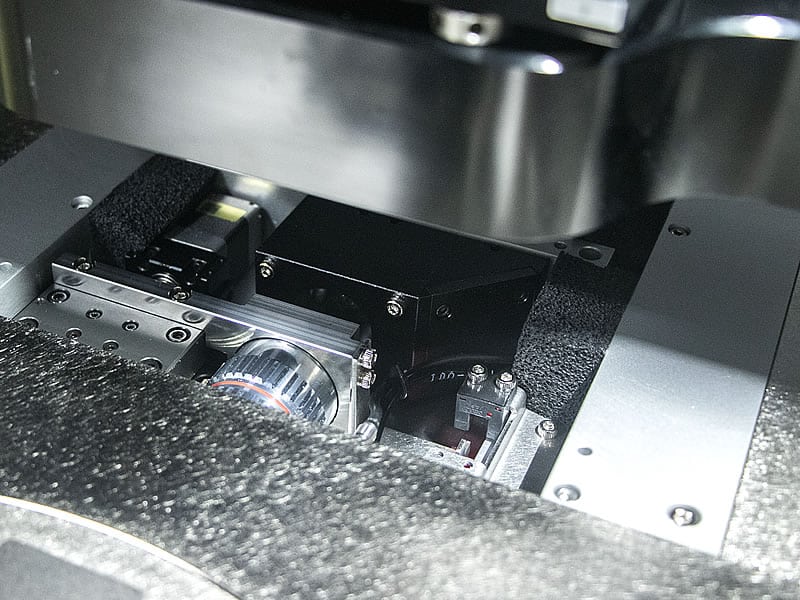

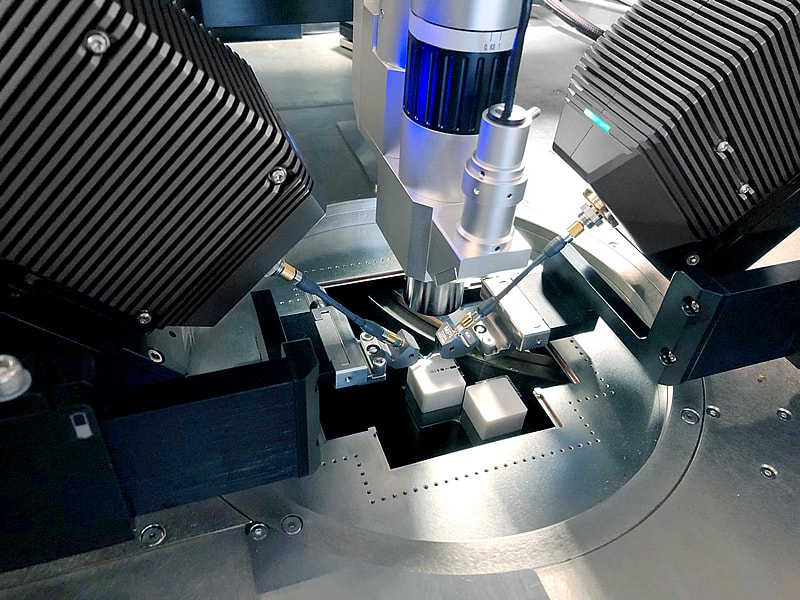

Advanced Alignment

Advanced alignment features such as downward looking off-axis and chuck mounted upward looking cameras make the TS2000-IFE an ideal platform for testing within complex RF, mmW and SiPh measurement configurations. Decades of experience from the MPI Photonics Automation Division making such features highly reliable.

Wafer-ID reader is also available as an option.

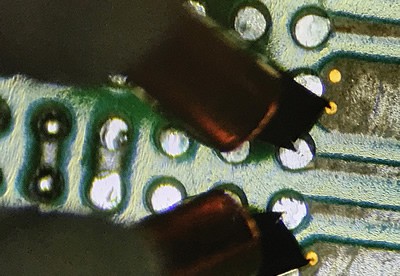

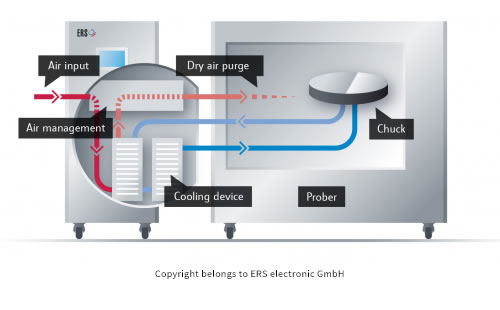

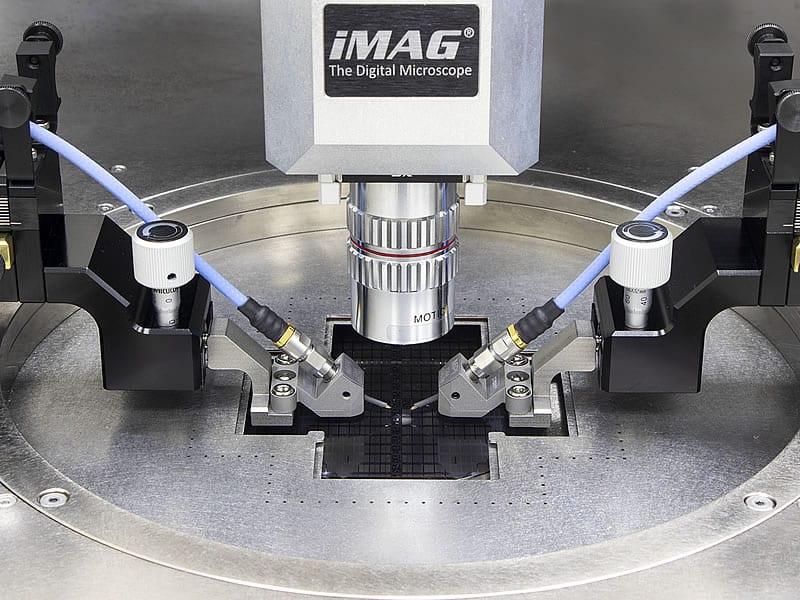

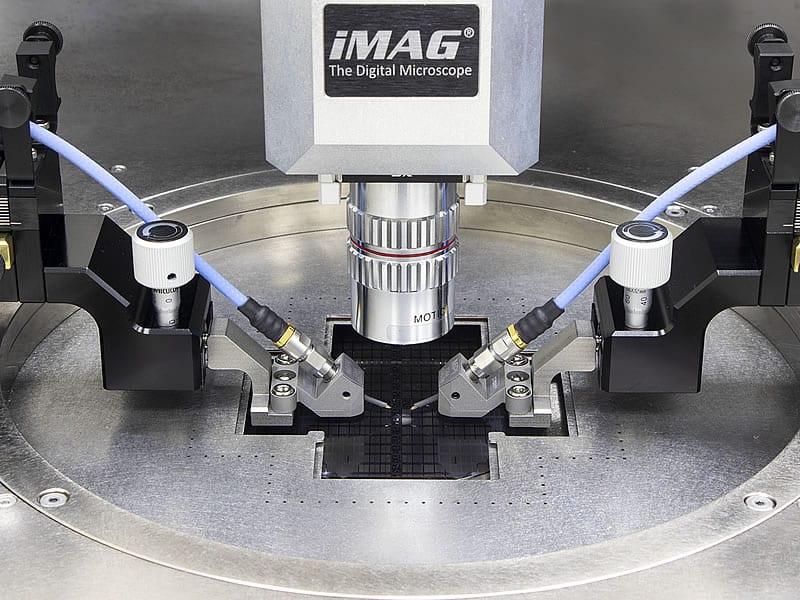

IceFreeEnvironment™

Incorporating MPI’s IceFreeEnvironment™ the TS2000-IFE accommodates testing with MicroPositioners and probe card simultaneously over a wide temperature range of -60°C to +300°C.

The design shortens the signal path thus making the probe station an ideal choice for mmW and/or load-pull applications.

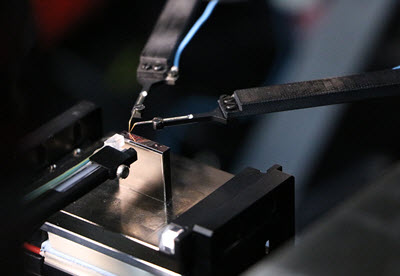

Thermal Chuck Integration

Due to the smart chiller integration, the TS2000-IFE provides optimized footprint for saving valuable space in the lab plus fastest thermal transition time.

MPI and ERS designed together the new PRIME 200 mm chucks family, offering unsurpassed thermal flexibility with reduced soaking time by 60% and the largest variety of thermal ranges and field upgrades.

The thermal system can be operated by using the fully integrated touchscreen display, placed at convenient location in front of the operator for fast operation and immediate feedback.

Integrated Hardware Control Panel

The intelligent hardware control panel is completed integrated into the probe system and is designed based on decades of experience and customer interactions to provide faster, safer and convenient system control and test operation. The keyboard and mouse are strategically located to control the software if necessary and will also control the Windows® based instrumentation.

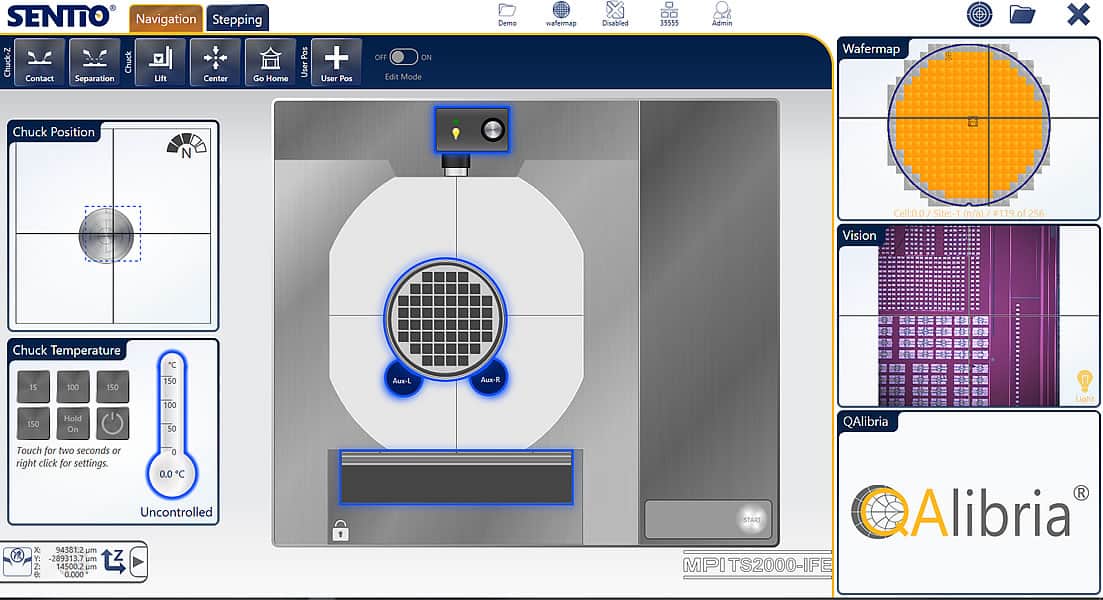

MPI SENTIO®

By using a novel approach based on simplicity and truly intuitive operation, MPI was first to develop a revolutionary multi-touch prober control software suite to address today’s challenges of operating complex probe test systems.

MPI goal is to save significantly training time and makes the operators’ life as easy as possible, even by operating the fully-automatic TS2000-IFE probe stations.